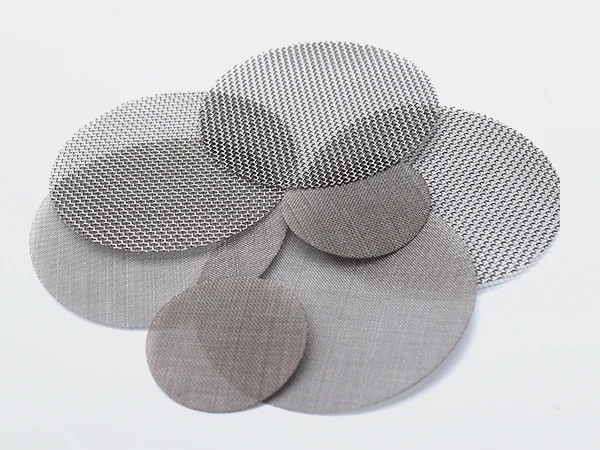

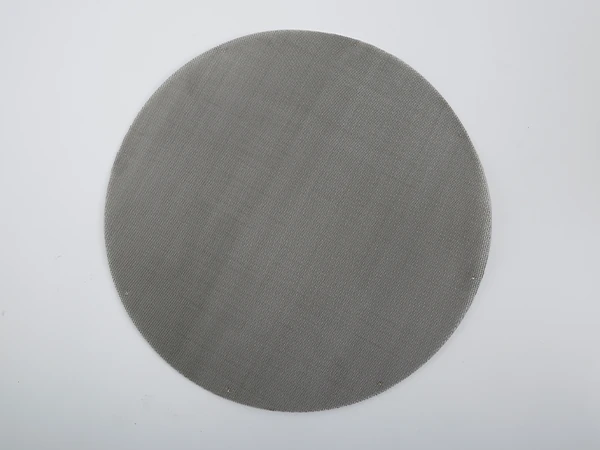

Round filter disc

Filter discs, filter cartridges, and filter elements are deep processing products made from woven wire mesh through processes such as cutting, spot welding, edging, and pleating to create square, rectangular, circular, or special shapes to meet specific needs.

We can provide deep processing woven wire mesh products that come in single-layer or multi-layer, various materials, mesh sizes, and weave methods.

Filter discs are composed of single-layer or multi-layer stainless steel woven mesh and are widely used in the fields of polymer processing and melt filtration. We offer filter discs in a variety of specifications and weave methods to meet different filtration needs. The shape and size of the filter discs can be customized according to requirements.

Round filter disc

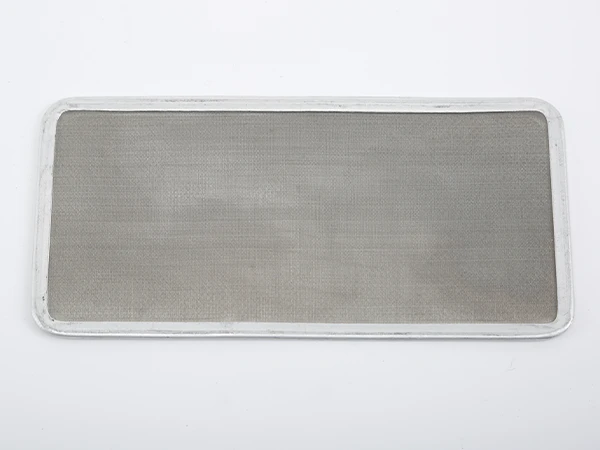

Rectangular filter disc

Kidney-shaped filter disc

Single-layer filter disc

Multi-layer filter disc

Edged filter disc

Filter cartridge is a commonly used filtration device, primarily used to remove solid particles from fluids (gases or liquids), and is widely used in water treatment, food and beverage industries, etc.

Single-layer filter cartridge

Multi-layer filter cartridge

Due to its excellent corrosion resistance and filtration performance, stainless steel filter element has become one of the most commonly used industrial filter elements. It is widely used in various filtration applications, such as chemicals, high-viscosity liquids, and the food and beverage industry.

According to the structure of the filter element, we offer pleated filter elements and cylindrical filter elements to meet your specific filtration requirements.

Cylindrical filter element

Pleated filter element

| Table 1: Specifications of Stainless Steel Square Weave Mesh | |||||||

| Mesh Count | Wire Diameter | Aperture | Open Area | Max. Width | Theoretical Weight | ||

|---|---|---|---|---|---|---|---|

| Inch | mm | Inch | mm | % | mm | kg/sqm | |

| 1 × 1 | 0.08" | 2.03 | 0.92" | 23.37 | 84.6 | 2000 | 2.06 |

| 2 × 2 | 0.063" | 1.6 | 0.437" | 11.1 | 76.4 | 2000 | 2.56 |

| 3 × 3 | 0.054" | 1.37 | 0.279" | 7.09 | 70.1 | 2000 | 2.82 |

| 4 × 4 | 0.063" | 1.6 | 0.187" | 4.75 | 56 | 2000 | 5.12 |

| 4 × 4 | 0.047" | 1.19 | 0.203" | 5.16 | 65.9 | 2000 | 2.83 |

| 5 × 5 | 0.041" | 1.04 | 0.159" | 4.04 | 63.2 | 2000 | 2.7 |

| 6 × 6 | 0.035" | 0.89 | 0.132" | 3.35 | 62.7 | 2000 | 2.38 |

| 8 × 8 | 0.028" | 0.71 | 0.097" | 2.46 | 60.2 | 2000 | 2.02 |

| 10 × 10 | 0.025" | 0.64 | 0.075" | 1.91 | 56.3 | 2000 | 2.05 |

| 10 × 10 | 0.02" | 0.51 | 0.08" | 2.03 | 64 | 2000 | 1.3 |

| 12 × 12 | 0.023" | 0.584 | 0.06" | 1.52 | 51.8 | 2000 | 2.05 |

| 12 × 12 | 0.02" | 0.508 | 0.063" | 1.6 | 57.2 | 2000 | 1.55 |

| 14 × 14 | 0.023" | 0.584 | 0.048" | 1.22 | 45.2 | 2000 | 2.39 |

| 14 × 14 | 0.02" | 0.508 | 0.051" | 1.3 | 51 | 2000 | 1.81 |

| 16 × 16 | 0.018" | 0.457 | 0.0445" | 1.13 | 50.7 | 2000 | 1.67 |

| 18 × 18 | 0.017" | 0.432 | 0.0386" | 0.98 | 48.3 | 2000 | 1.68 |

| 20 × 20 | 0.02" | 0.508 | 0.03" | 0.76 | 36 | 2000 | 2.58 |

| 20 × 20 | 0.016" | 0.406 | 0.034" | 0.86 | 46.2 | 2000 | 1.65 |

| 24 × 24 | 0.014" | 0.356 | 0.0277" | 0.7 | 44.2 | 2000 | 1.52 |

| 30 × 30 | 0.013" | 0.33 | 0.0203" | 0.52 | 37.1 | 2000 | 1.63 |

| 30 × 30 | 0.012" | 0.305 | 0.0213" | 0.54 | 40.8 | 2000 | 1.4 |

| 30 × 30 | 0.009" | 0.229 | 0.0243" | 0.62 | 53.1 | 2000 | 0.79 |

| 35 × 35 | 0.011" | 0.279 | 0.0176" | 0.45 | 37.9 | 2000 | 1.36 |

| 40 × 40 | 0.01" | 0.254 | 0.015" | 0.38 | 36 | 2000 | 1.29 |

| 50 × 50 | 0.009" | 0.229 | 0.011" | 0.28 | 30.3 | 2000 | 1.31 |

| 50 × 50 | 0.008" | 0.203 | 0.012" | 0.31 | 36 | 2000 | 1.03 |

| 60 × 60 | 0.0075" | 0.191 | 0.0092" | 0.23 | 30.5 | 2000 | 1.09 |

| 60 × 60 | 0.007" | 0.178 | 0.0097" | 0.25 | 33.9 | 2000 | 0.95 |

| 70 × 70 | 0.0065" | 0.165 | 0.0078" | 0.2 | 29.8 | 2000 | 0.95 |

| 80 × 80 | 0.0065" | 0.165 | 0.006" | 0.15 | 23 | 2000 | 1.09 |

| 80 × 80 | 0.0055" | 0.14 | 0.007" | 0.18 | 31.4 | 2000 | 0.78 |

| 90 × 90 | 0.005" | 0.127 | 0.0061" | 0.16 | 30.1 | 2000 | 0.73 |

| 100 × 100 | 0.0045" | 0.114 | 0.0055" | 0.14 | 30.3 | 2000 | 0.65 |

| 100 × 100 | 0.004" | 0.102 | 0.006" | 0.15 | 36 | 2000 | 0.52 |

| 100 × 100 | 0.0035" | 0.089 | 0.0065" | 0.17 | 42.3 | 2000 | 0.4 |

| 110 × 110 | 0.004" | 0.1016 | 0.0051" | 0.1295 | 30.7 | 2000 | 0.57 |

| 120 × 120 | 0.0037" | 0.094 | 0.0064" | 0.1168 | 30.7 | 2000 | 0.53 |

| 150 × 150 | 0.0026" | 0.066 | 0.0041" | 0.1041 | 37.4 | 2000 | 0.33 |

| 160 × 160 | 0.0025" | 0.0635 | 0.0038" | 0.0965 | 36.4 | 2000 | 0.32 |

| 180 × 180 | 0.0023" | 0.0584 | 0.0033" | 0.0838 | 34.7 | 2000 | 0.31 |

| 200 × 200 | 0.0021" | 0.0533 | 0.0029" | 0.0737 | 33.6 | 2000 | 0.28 |

| 250 × 250 | 0.0016" | 0.0406 | 0.0024" | 0.061 | 36 | 2000 | 0.21 |

| 270 × 270 | 0.0016" | 0.0406 | 0.0021" | 0.0533 | 32.2 | 2000 | 0.22 |

| 300 × 300 | 0.0051" | 0.0381 | 0.0018" | 0.0457 | 29.7 | 2000 | 0.22 |

| 325 × 325 | 0.0014" | 0.0356 | 0.0017" | 0.0432 | 30 | 2000 | 0.21 |

| 400 × 400 | 0.001" | 0.0254 | 0.0015" | 0.37 | 36 | 2000 | 0.13 |

| 500 × 500 | 0.001" | 0.0254 | 0.001" | 0.0254 | 25 | 2000 | 0.16 |

| 635 × 635 | 0.0008" | 0.0203 | 0.0008" | 0.0203 | 25 | 2000 | 0.13 |

| Table 2: Specifications of Stainless Steel Dutch Weave Mesh | |||

| Mesh Count | Wire Diameter | Mass | Filter Rating |

|---|---|---|---|

| mm | kg/m 2 | μm | |

| 6 × 45 | 0.10 × 0.60 | 5.3 | 400 |

| 72 × 15 | 0.45 × 0.45 | 4.5 | 350 |

| 132 × 17 | 0.30 × 0.45 | 4.1 | 240 |

| 12 × 64 | 0.60 × 0.40 | 4.2 | 200 |

| 152 × 24 | 0.30 × 0.40 | 3.6 | 190 |

| 14 × 88 | 0.50 × 0.35 | 2.1 | 150 |

| 12 × 90 | 0.45 × 0.30 | 2.6 | 135 |

| 13 × 100 | 0.45 × 0.28 | 2.58 | 125 |

| 14 × 100 | 0.40 × 0.28 | 2.5 | 120 |

| 16 × 125 | 0.35 × 0.22 | 2 | 110 |

| 22 × 150 | 0.30 × 0.18 | 2 | 100 |

| 20 × 250 | 0.25 × 0.20 | 2.8 | 100 |

| 130 × 35 | 0.20 × 0.40 | 3.1 | 90 |

| 24 × 110 | 0.35 × 0.25 | 2.65 | 80 |

| 30 × 330 | 0.25 × 0.16 | 2.55 | 80 |

| 50 × 400 | 0.20 × 0.14 | 2.14 | 70 |

| 25 × 170 | 0.25 × 0.16 | 1.45 | 70 |

| 30 × 150 | 0.23 × 0.18 | 1.6 | 65 |

| 260 × 40 | 0.15 × 0.25 | 2.15 | 65 |

| 40 × 200 | 0.18 × 0.12 | 1.3 | 55 |

| 50 × 230 | 0.18 × 0.12 | 1.23 | 50 |

| 400 × 125 | 0.065 × 0.10 | 0.7 | 50 |

| 50 × 600 | 0.14 × 0.080 | 1.3 | 45 |

| 50 × 250 | 0.14 × 0.11 | 0.9 | 40 |

| 80 × 400 | 0.12 × 0.07 | 0.7 | 35 |

| 80 × 700 | 0.11 × 0.076 | 1.21 | 25 |

| 165 × 800 | 0.07 × 0.050 | 0.7 | 15 |

| 165 × 1400 | 0.07 × 0.040 | 0.76 | 10 |

| 200 × 1400 | 0.07 × 0.040 | 0.8 | 5 |

| 325 × 2300 | 0.035 × 0.025 | 0.48 | 2 |