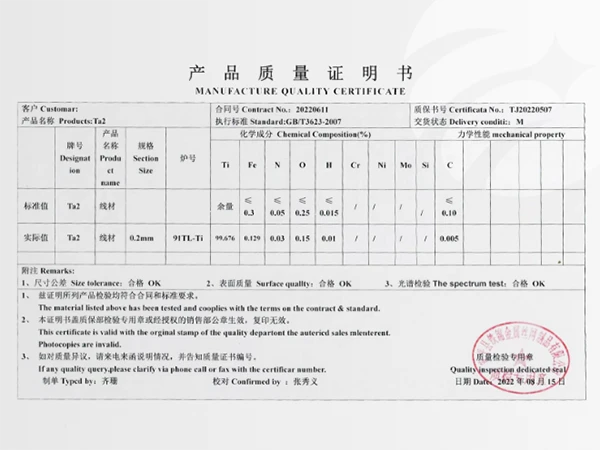

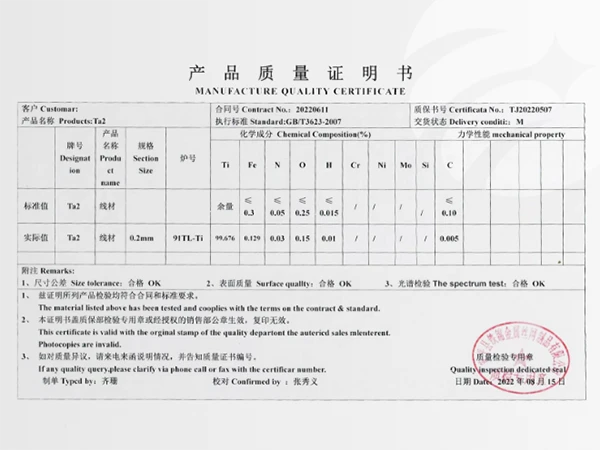

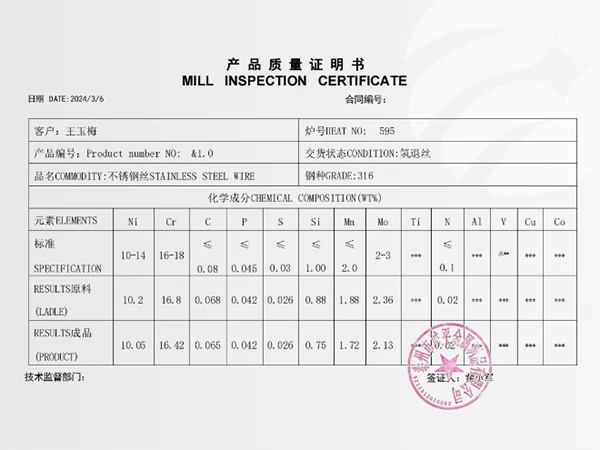

Mill certificate

Quality control is a critical process to ensure that products meet international standards and customer expectations. In addition, it is also the cornerstone of maintaining brand reputation and market competitiveness. Our company consistently adheres to the highest quality standards, with meticulous control at every step, from raw material selection to finished product testing.

Every product represents our pursuit of excellence and our commitment to customers, ensuring that each batch of woven mesh performs excellently under stringent working conditions. We are committed to providing high-quality products that exceed expectations to build and maintain long-term customer trust.

Our quality control system first ensures the quality of raw materials, which are sourced from reliable industry-leading companies.

Mill certificate

Mill certificate

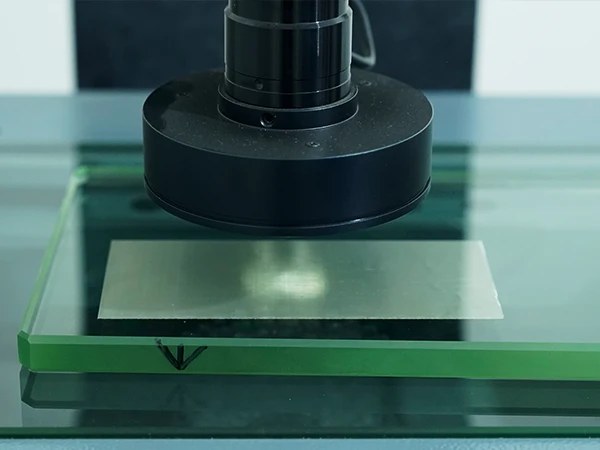

Chemical composition test

During the production process, in addition to controlling the quality of raw materials, we strictly adhere to corporate principles and international production standards to ensure that all key parameters of the woven mesh meet the specified requirements.

Raw Material Standards

Quality Standards

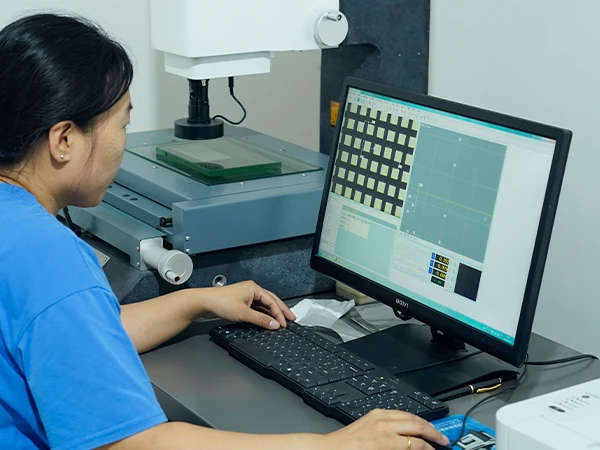

We are equipped with professional testing devices and staff to conduct quality control on woven mesh products,and ensure superior product quality.

Chemical composition inspection

Woven mesh roll width inspection

Wire diameter inspection after drawing

Mesh opening size inspection

Woven mesh roll length inspection

Our warehouse has designated areas for storing raw materials and finished products. Each product is labeled to ensure it can be quickly located. Our inventory is well-stocked, allowing us to meet urgent orders.

Woven mesh warehouse

Raw material storage area

Finished product storage area

Our woven mesh products are usually packaged with plastic film. For products with special purposes, we use kraft paper packaging to prevent damage during transportation.

Plastic packaging

Kraft paper packaging

Wooden box packaging

We provide comprehensive services and support to help customers understand the performance, usage, and installation methods of the products, and quickly respond to customer inquiries.