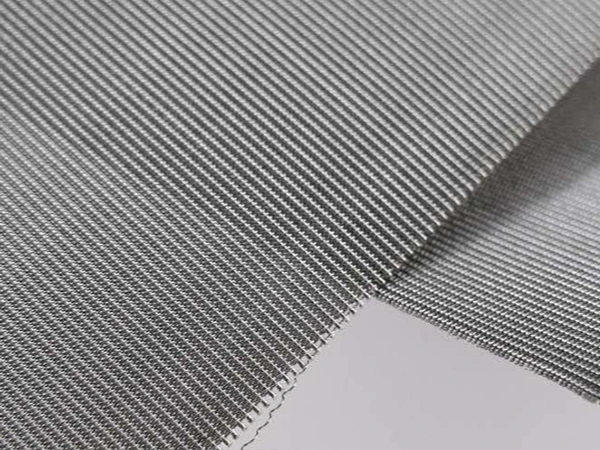

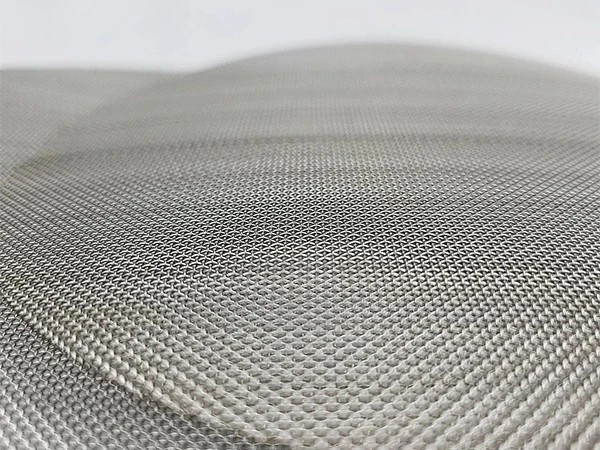

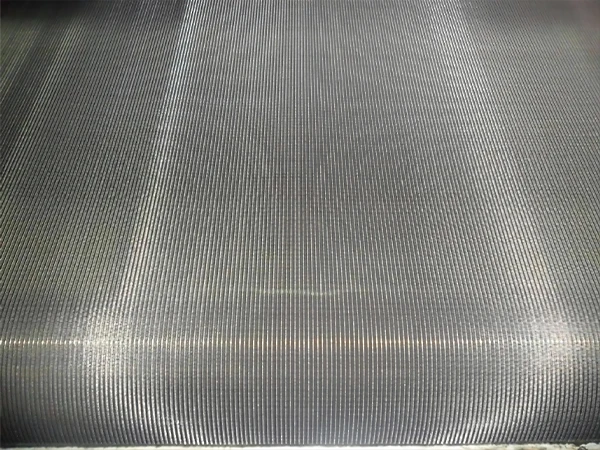

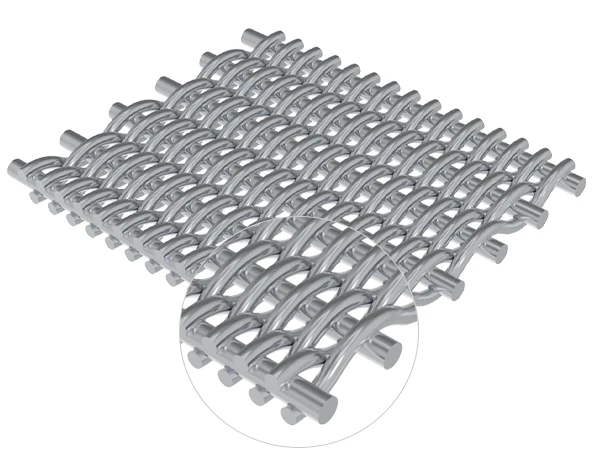

Plain dutch weave mesh is woven by alternating one warp wire over and under one weft wire , its warp wire is larger than the weft wire, providing higher filtration grade and strength.

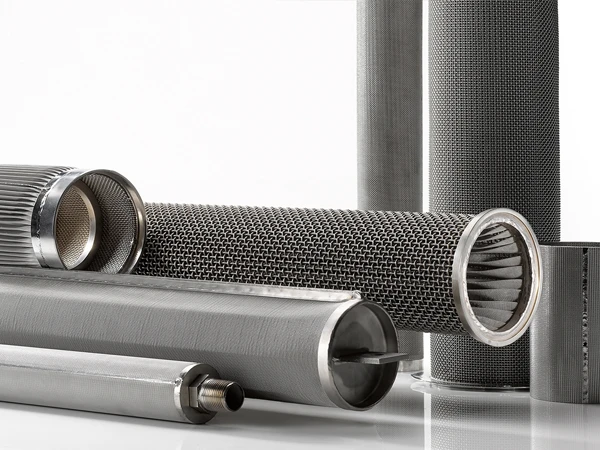

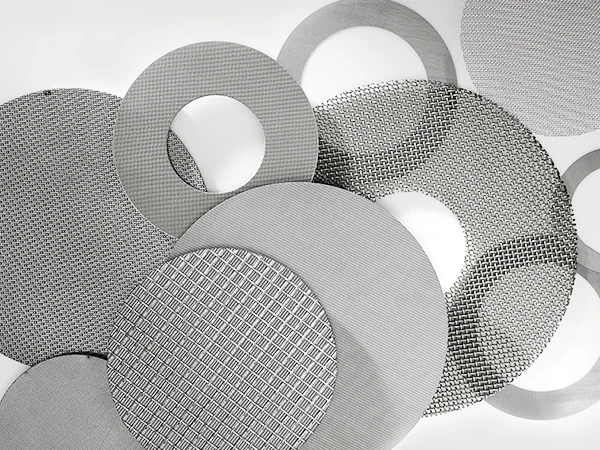

It can be used as a reinforcement layer or filtration layer in metal sintered mesh, extruder screens, etc.