Woven meh deep processing refers to the techniques of making woven mesh into round square, or special shapes through cutting, stamping, welding, and edging to meet specific application requirements. Deep-processing woven mesh products are often used in combination with various equipment to achieve the purposes of screening and filtration.

Using professional slitting machines, woven mesh is sliced into strips of different specifications and sizes to facilitate subsequent processing and use.

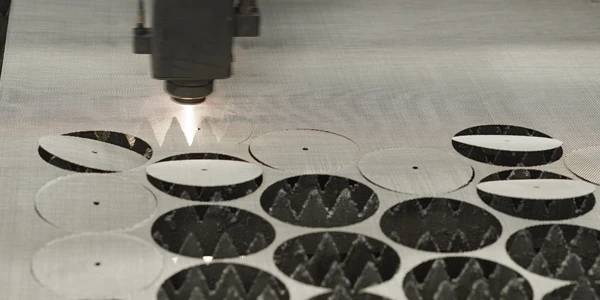

Laser cutting is a technology that uses a laser beam to cut the woven mesh into the desired shapes. Laser cutting has small slits, high precision, and smooth cuts, eliminating the need for further processing. It is often used to manufacture special-shaped filter elements.

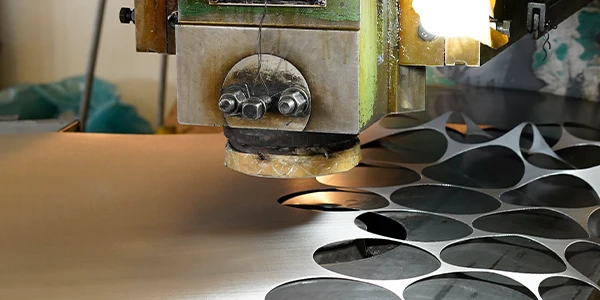

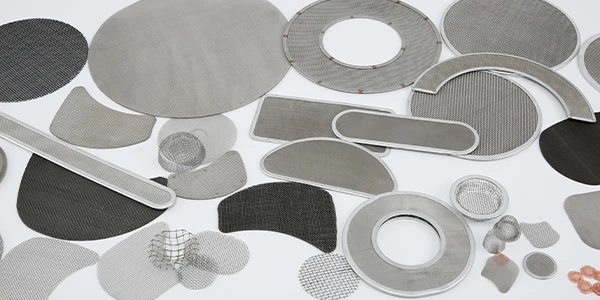

The stamping operation of woven mesh mainly utilizes stamping equipment and dies of different shapes (such as round and square) to apply pressure processing to the woven mesh, thereby producing deep-processing woven mesh products of various shapes.

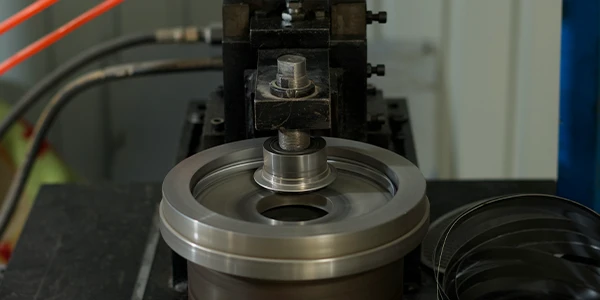

The edging operation reinforces the edges of the cut woven mesh, making the cut woven mesh more robust and preventing deformation caused by stretching and other operations. Edged products consist of single-layer or multi-layer filter discs, which are easy to disassemble and clean, and have a long service life.

The forming of woven mesh refers to the process of shaping the mesh into specific shapes through operations such as bending, stamping, and welding using specialized machines such as stamping and welding equipment. Common shapes include sheet, cylindrical, conical, etc.

Spot welding refers to the method of connecting multiple layers of filter discs by multiple resistance welding at the intersection points of the woven mesh, increasing the strength and stability of the woven mesh. It is a common welding method for metal woven mesh.

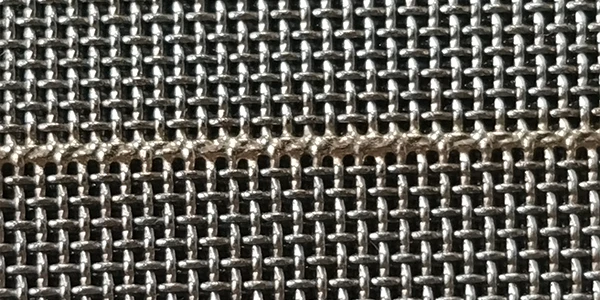

Edge welding uses resistance welding technology to connect the edges of stainless steel wires without interruption or gaps. Spot welding or seam welding techniques can also be used. Edge welding not only maintains the flatness of the mesh surface but also makes the structure more robust. It is commonly used in the manufacture of filter cartridges and electronic components.

Pleating refers to the technique of folding the woven mesh into a series of uniform pleats with a specialized pleating machine. Pleating increases the surface area of the mesh, thereby enhancing its filtration capacity. It is suitable for high-efficiency filtration applications such as air filters, liquid filters, and hydraulic filters.

We can provide woven mesh custom designs based on your specific usage requirements. First, it is necessary to determine the material of the product, the size and shape of the mesh, and the surface treatment method to ensure that the woven mesh achieves the best performance and effectiveness.