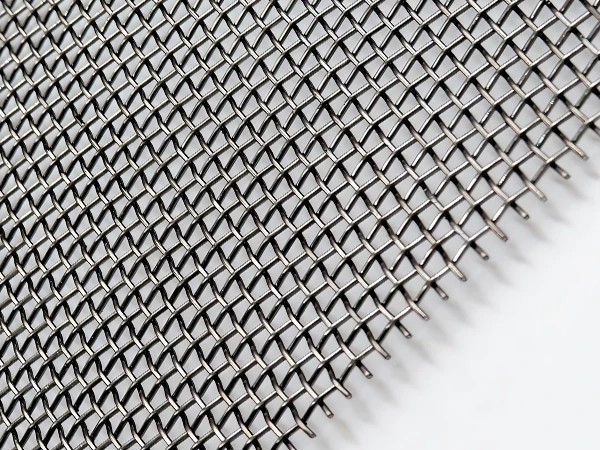

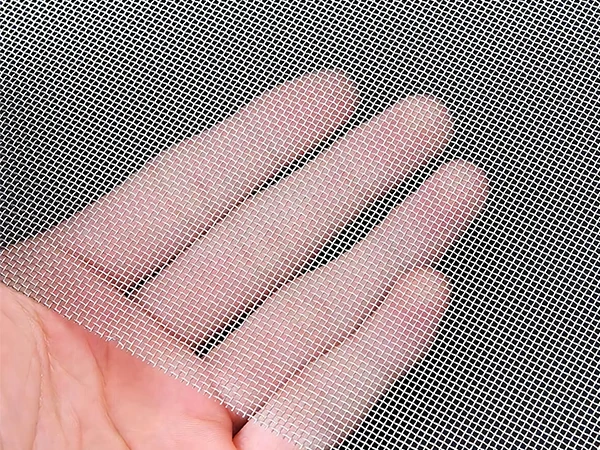

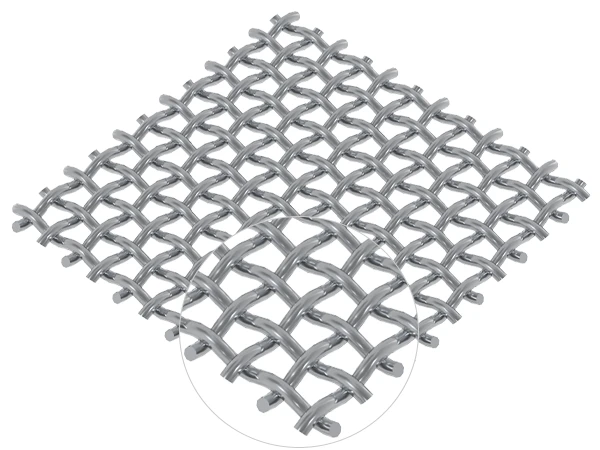

Stainless steel plain weave mesh is woven by alternating one warp wire over and under one weft wire, forming a 90-degree angle. The warp and weft wires have the same diameter, and the opening size is consistent.

It is commonly used for screening and coarse filtration.