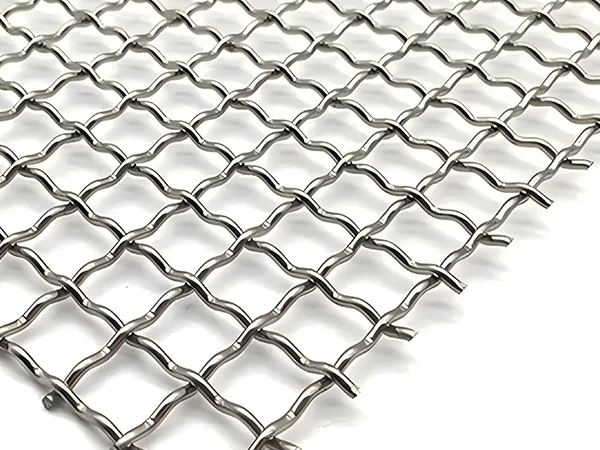

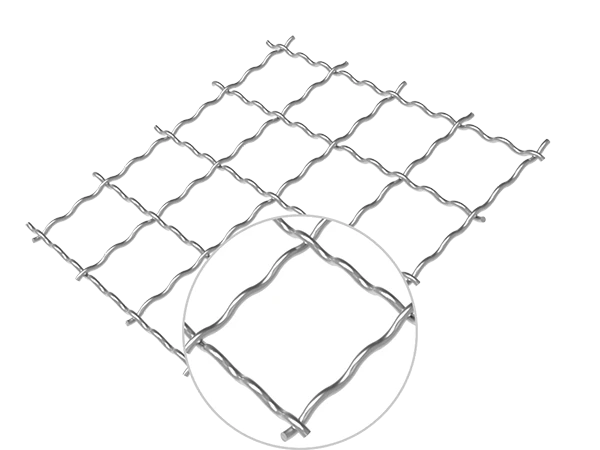

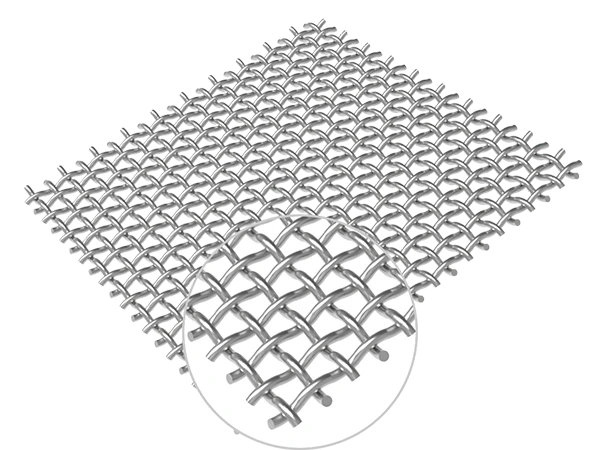

A weaving method where each metal wire is precisely crimped and positioned according to the predetermined mesh size before weaving. Each metal wire is precisely crimped at the interlacing points to ensure that the wires maintain a fixed cross position during weaving.

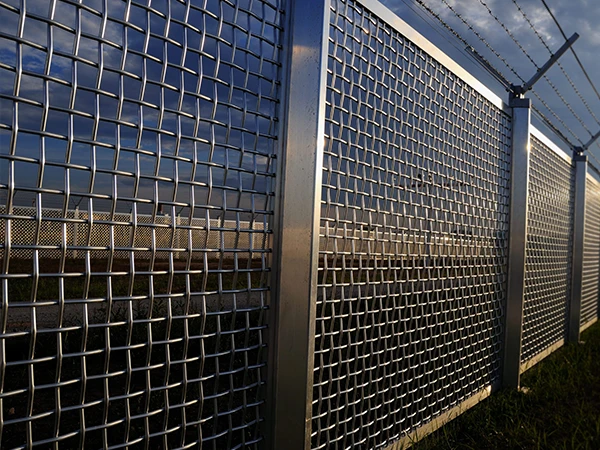

It is commonly used in industrial screening, construction protection, and machinery equipment isolation.