Since its establishment, Eastar Filtration Industry Co., Ltd. has built a good reputation in the woven mesh manufacturing industry. We have advanced production equipment and a team of experienced professionals. Our mission is to support and enhance our customers' business operations through high-quality products and first-class customer services.

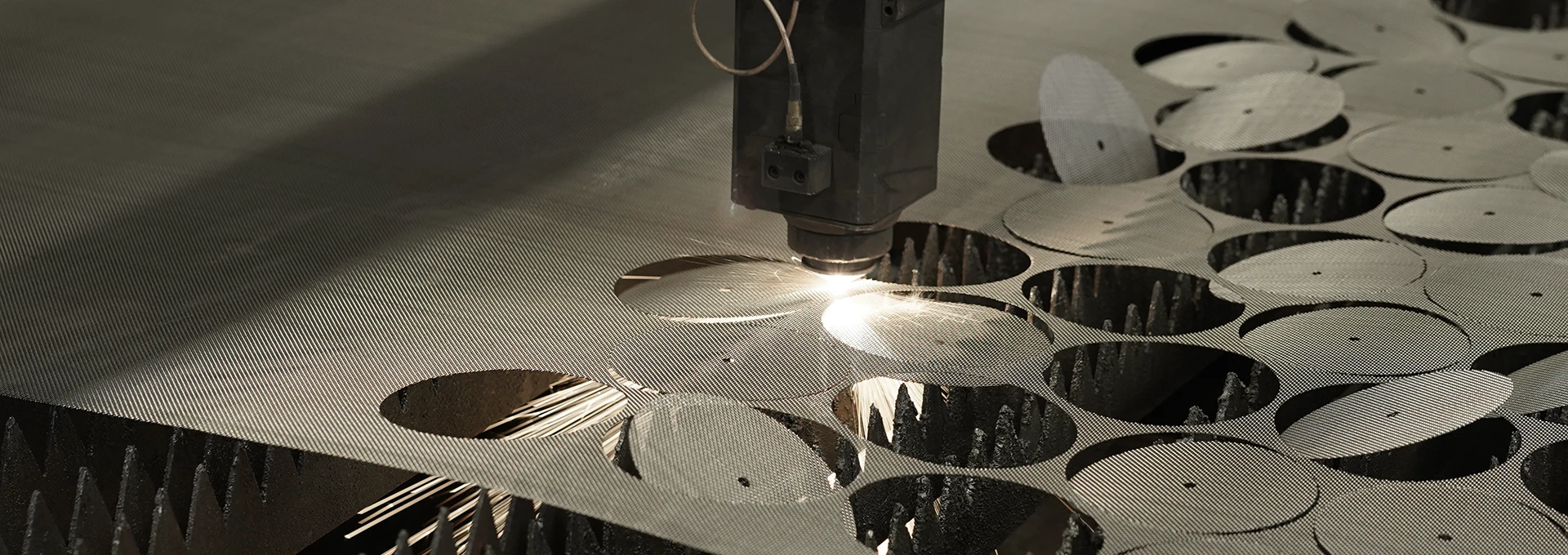

We are committed to providing high-quality woven mesh products to our customers through advanced production technology and strict quality control.

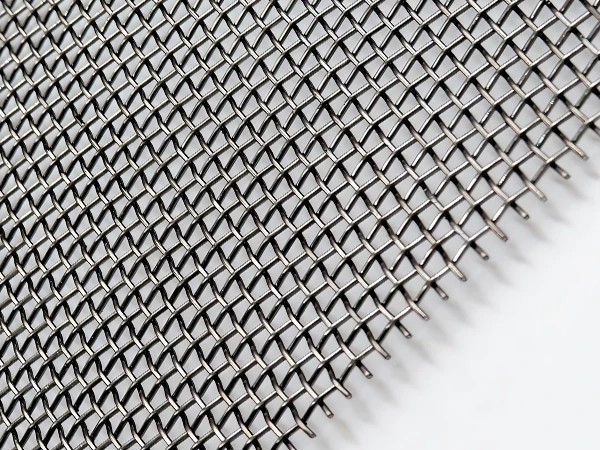

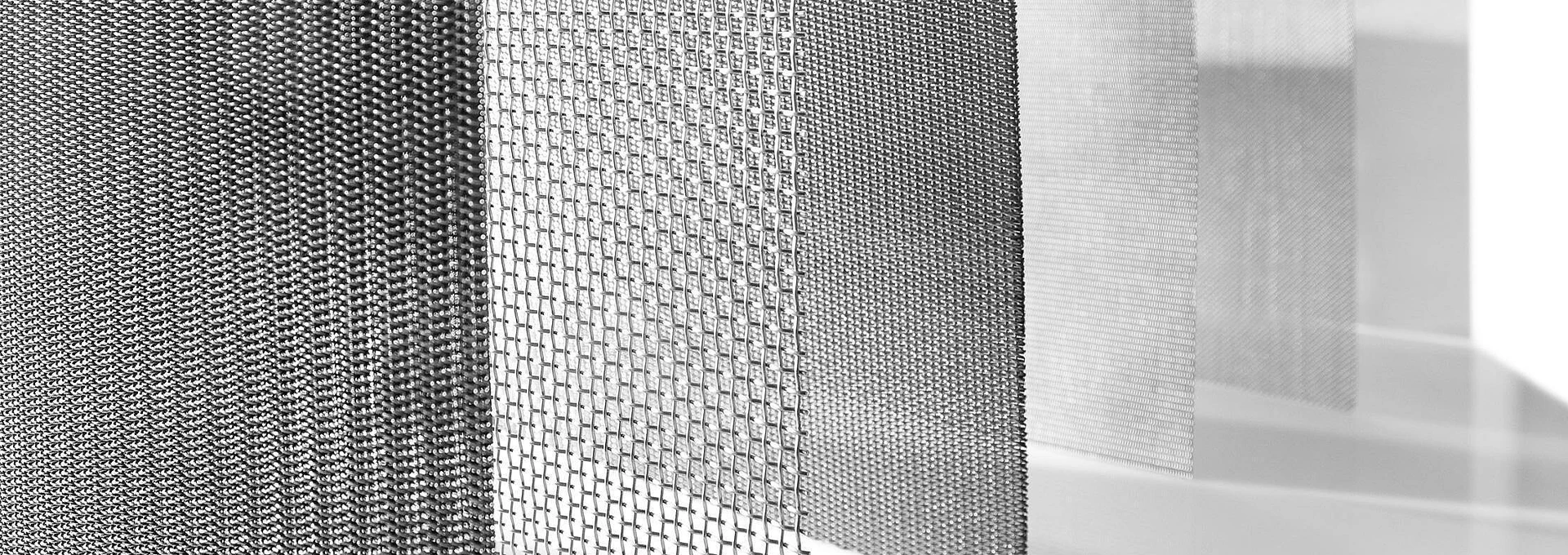

We offer a diverse range of products, whether for screening, filtration, or other applications. We provide the highest quality woven mesh products to meet your needs. Additionally, we offer custom services, tailoring deep-processing woven mesh products according to the specific requirements of our customers.

We consistently adhere to the highest quality standards, ensuring that our products meet international standards and customer expectations.

Our raw materials are sourced from industry-leading companies, and the woven mesh we produce meets international standards. We strictly follow international standards to provide customers with the highest quality woven mesh, meeting their wire mesh needs and enhancing customer satisfaction.

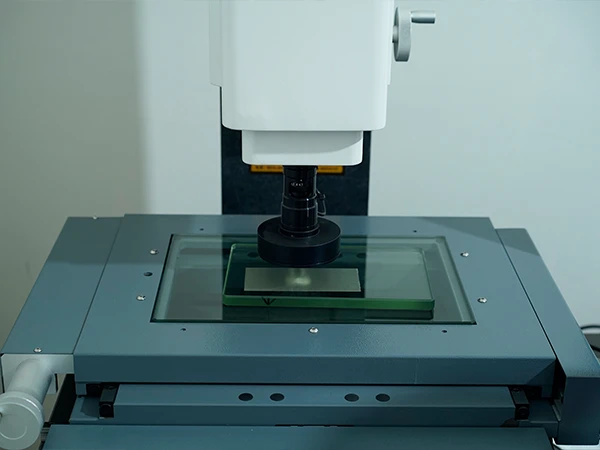

During the production process, our experienced technicians frequently inspect and test the quality of our woven mesh to ensure that our products meet all necessary requirements. Our production strictly comply with international standards, ensuring that all key parameters are professionally controlled.

To ensure that we provide the highest quality products to our customers, we fully implement our Quality Control (QC) system. Our QC system is equipped with advanced testing machines, professional staff, and rigorous QC assessment personnel, ensuring the high quality of our woven mesh.

We have a comprehensive, strict packaging system. Generally, our woven mesh products are packaged with materials such as plastic film and kraft paper. To ensure the safe arrival of goods at the customer's location to the greatest extent, we use proper packaging that meets customer requirements.

We divide our warehouse into different sections for zoned management, with each product labeled for easy tracking and management. We ensure that our products are kept in optimal condition, with a large inventory available to meet urgent orders, ready for loading and delivery at any time.

When you purchase woven mesh products, you not only receive high-quality products but also benefit from our comprehensive after-sales support. Our experienced professionals provide prompt after-sales service to answer your questions and offer solutions to any issues with the products.

As a professional manufacturer in the field of woven mesh, we have earned the trust of our customers through strict standards, excellent quality, and advanced technology.

Our materials are sourced from well-known companies.

Our woven mesh complies with international standards.

We have professional devices and teams.

We offer the lowest ex-factory price as far as possible.

Our storage can meet the needs of urgent orders.